Robot body encoder special flexible cable

characteristic:

Bending resistant Drag resistant Oil resistant Flame retardant (-40~+80°C)

Rocking Resistance Shielded 300V Rohs Reach

Conductor: Tinned copper or bare copper

Sectional view:

Insulation: (Elastomer Material) or (Teflon Material)

Sheath: (polyurethane) or (polyvinyl chloride)

Shield: tinned copper wire

Rated voltage: 300V

Withstand voltage AC: 2.0KV/min

Towchain times: 20 million times or more

Flexible drag chain cable test standard

Mobile bending test standard (towline test)

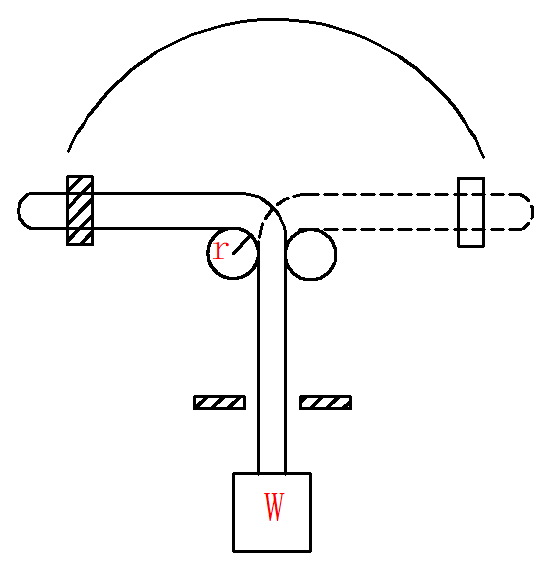

Simulate the conditions of the cable bending movement in the drag chain. Test Take the sample from the finished product and fix it on the drag chain test device according to the following figure. The bending radius is r=7.5D; S=600mm; the speed is 90 bpm. carry out testing.

r=bending radius

S= drag chain travel

D= cable outer diameter

The number of round-trips exceeds 20 million times and no disconnection occurs.

90° bending test method

“Take the sample from the finished product, and fix it on the 90° bending test device according to the figure below. The other end shall hang the specified weight weight.” The bending radius and the weight weight refer to the customer's standard, and the device is bent at 40 times/min. test.

r=弯曲半径

w=砝码

Wire model | Conductor structure | Core diameter | Conductor resistance Ω/KM | Core pairs | Complete outer diameter | Recommended bending radius |

26 | 7/4/0.08 | 1.05 | ≤150 | 2 | 5.90 | 44.2 |

3 | 6.50 | 48.8 | ||||

4 | 7.00 | 52.6 | ||||

5 | 7.70 | 57.8 | ||||

6 | 8.20 | 61.6 | ||||

7 | 8.70 | 65.2 | ||||

10 | 10.50 | 78.8 | ||||

12 | 12.00 | 90 | ||||

24 | 7/6/0.08 | 1.20 | ≤94.2 | 2 | 6.30 | 47.4 |

3 | 7.10 | 53.4 | ||||

4 | 7.80 | 58.6 | ||||

5 | 8.40 | 63 | ||||

6 | 9.10 | 68.4 | ||||

7 | 9.60 | 72 | ||||

10 | 11.80 | 88.6 | ||||

12 | 13.60 | 102 | ||||

22 | 7/10/0.08 | 1.45 | ≤59.4 | 2 | 7.00 | 52.6 |

3 | 8.20 | 61.6 | ||||

4 | 8.90 | 66.8 | ||||

5 | 9.60 | 72 | ||||

6 | 10.30 | 77.4 | ||||

7 | 11.30 | 84.8 | ||||

10 | 13.80 | 104 | ||||

12 | 15.80 | 118.6 | ||||

20 | 7/15/0.08 | 1.80 | ≤36.7 | 2 | 8.60 | 64.6 |

3 | 9.00 | 67.6 | ||||

4 | 11.00 | 82.6 | ||||

5 | 12.50 | 93.8 | ||||

6 | 13.00 | 97.6 | ||||

7 | 13.80 | 104 | ||||

10 | 16.00 | 120 | ||||

12 | 18.30 | 137.4 | ||||

18 | 7/15/0.10 | 2.10 | ≤23.2 | 2 | 9.50 | 71.4 |

3 | 11.00 | 82.6 | ||||

4 | 12.80 | 96 | ||||

5 | 13.80 | 103.6 | ||||

6 | 15.00 | 112.6 | ||||

7 | 16.00 | 120 | ||||

10 | 18.30 | 137.4 | ||||

12 | 20 | 150 | ||||

16 | 7/24/0.10 | 2.50 | ≤14.6 | 2 | 9.30 | 70 |

3 | 13.00 | 97.6 | ||||

4 | 15.20 | 114 | ||||

5 | 16.30 | 122 | ||||

6 | 17.00 | 127.6 | ||||

7 | 18.30 | 137.4 | ||||

10 | 21.00 | 157.6 | ||||

12 | 23.00 | 172.6 | ||||

14 | 7/38/0.10 | 3.00 | ≤8.96 | 2 | 13.80 | 103.6 |

3 | 15.60 | 117 | ||||

4 | 17.20 | 129 | ||||

5 | 18.60 | 139.2 | ||||

6 | 20.00 | 150 | ||||

7 | 21.00 | 157.6 | ||||

10 | 24.00 | 180 | ||||

12 | 26.00 | 195 | ||||

12 | 7/60/0.10 | 3.60 | ≤5.64 | 2 | 16.00 | 120 |

3 | 18.30 | 137.4 | ||||

4 | 20.50 | 153.8 | ||||

5 | 22.00 | 165 | ||||

6 | 24.00 | 180 | ||||

7 | 25.00 | 187.6 |